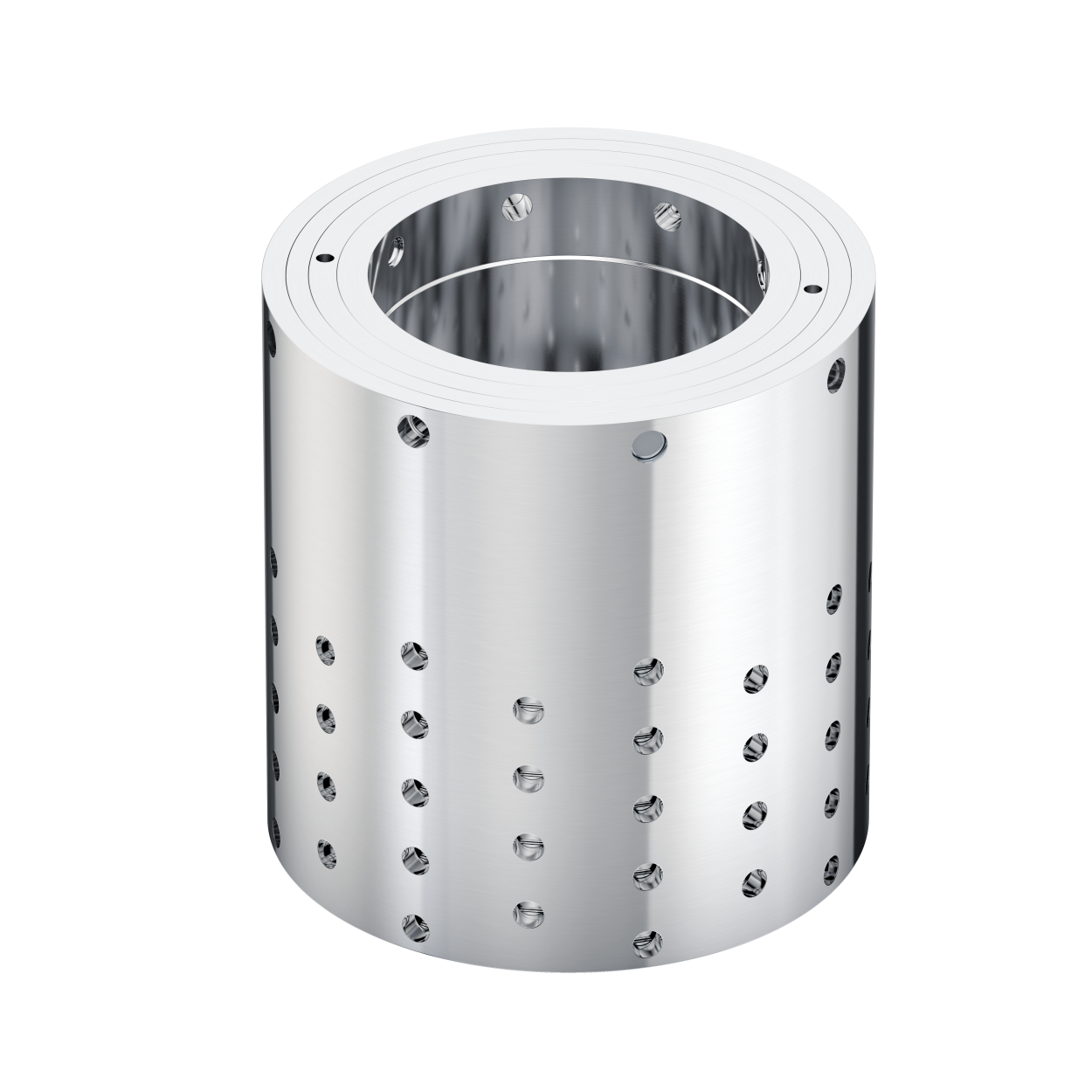

SonicDark

The SonicDark Cavitation Resistant Trim is designed to destroy the energy in the liquid/vapor mixture by arranging jets of liquid to hit each other. The diametrically opposed holes guide the liquid flow to the center of the cage so that it does not impinge upon the metal trim components.

This cage can also be designed specifically for noise reduction in the valve by separating the fluid into a calculated number of small jets.

Facts

- Cavitation Control – Liquid Service

- Size Range: 1” to 16”

- Pressure Class range: ANSI Class 150# to 2500#

- Material: Metal

- Custom engineered to meet customer specific requirements

ShockStream

The ShockStream Trim is built from concentric cylinders with precisely positioned and sized drilled holes for ultimate trim velocity control in order to reduce noise and vibration in demanding gas applications.

Noise and vibration reduction are achieved by a number of incorporated techniques for pressure drop staging, attenuation and frequency shifting.

Facts

- Noise & Vibration Control – Gas Service

- Size Range: 1” to 24”

- Pressure Class range: ANSI Class 150# to 2500#

- Material: Metal

- Custom engineered to meet customer specific requirements

DragonEye

The DragonEye Trim is built from concentric cylinders with precisely positioned and sized drilled holes, thus combining noise control and cavitation resistance in one valve.

The carefully designed flow path with precise reduction staging for high pressure drops, maintains pressure above the vapor pressure at all times never allowing cavitation to form.

Facts

- Noise & Cavitation Control – Liquid Service

- Size Range: 2” to 36”

- Pressure Class range: ANSI Class 150# to 2500#

- Material: Metal

- Custom engineered to meet customer specific requirements

FlowShark

The FlowShark is a multi-stage, tortuous path type of trim, consisting of stacked metal rings with distinctly shaped, custom designed passages. The various incorporated methods of Velocity Control in combination with the latest state-of-the-art manufacturing techniques have made the Atacama the most advanced Critical Service Trim currently available in the market.

Best in class for Critical Service Applications in the Energy Industry.

Facts

- The Ultimate Critical Service Trim

- Anti-cavitation and noise attenuation – Liquid & Gas Service

- Size Range: 1,5” to 36”

- Pressure Class range: ANSI Class 150# to 2500#

- Material: Metal

- Custom engineered to meet customer specific requirements