BG-H

HIGH Pressure

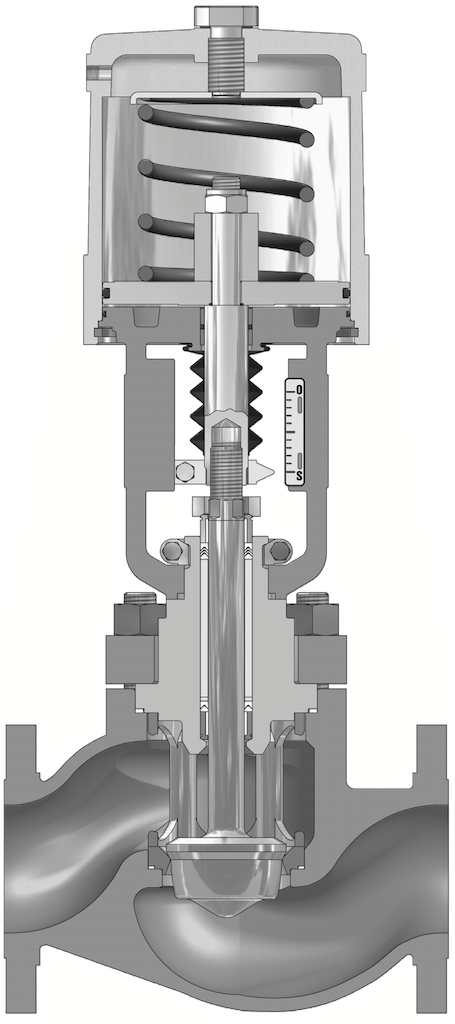

General & Severe Service Control Valve

Rugged

The GLS valve construction makes it less prone to corrosion attacks from process fluids when compared to conventional globe valves. When necessary, optional low-noise and anti-cavitation trim are also available.

Packing

The GLS series guiding system not only eliminates the disadvantages of a guiding system at the seat retainer, but the GLS guides, being well spaced and with large bearing support surfaces, eliminate the problems related to vibration in control valves.

Seating

In addition to providing accurate control, the concept of the GLS valve with a single and self-centering seat ensures exceptional shutoff capability, normally assisted by the fluid pressure.

Non Jamming Trim

The double upper guide system, located out of the flow passageway, ensures a perfect alignment of the plug stem, while providing considerable clearance between the plug head and the seat retainer, eliminating friction problems that exist in cage guided valves.

Quick & Easy

Valtek Sulamericana’s top-entry assembly design simplifies maintenance tasks. The clamped-in seat ring, secured by the seat retainer, as well as all other components of the valve and the actuator, do not require the use of special tools for their disassembly or reassembly.

Versatile

In addition to conventional globe-style bodies, angle-styles, three-ways, or steam jacketed bodies are also availablel these bodies are compliant with several standards relevant to face-to-face dimensions.

Specifications

Bonnet Types

Yoke Clamp

End Connections

Plug

Seat

Severe Service

Packing & Guiding Gaskets

Fugitive Emissions

Flow Characteristics

Flow Coefficients

Dimensions

Shipping Weights

Downloads

IOM

The GLS series is recognized as a high performance control valve in the oil, gas, power, and process industries, all the while boasting easy, quick, and economical maintenance. In contrast with other control valves operated by spring-diaphragm actuators, the GLS Series is operated by a double acting spring-cylinder actuator that takes advantage of its high pneumatic stiffness, which in turn ensures excellent and accurate positioning during throttling as well as fast and reliable response to changes in the control signal. As the actuator operates with an air supply pressure of up to 150 psi (10.3 Bar), the GLS Series provides the required force to ensure that the specified shutoff class, even under high differential pressures, is achieved.

While spring-diaphragm actuators depend entirely on spring force to close a valve, the GLS Series control valve combines spring force, air supply pressure, process process, and its self centering seat design to produce a high closing force, thus ensuring a high level of tightness. One of the most common application challenges associated with control valves is attributed to the selection of cage-guided systems. The close contact between the metallic surfaces of the seat retainer (cage) and the plug frequently results in friction wear and jamming. It is for this reason that the GLS Series has a double upper guide system that is located outside the flow path and completely eliminates direct contact between the plug and the seat retainer.

The double acting spring-cylinder actuator manufactured by Valtek Sulamericana for the GLS Series control valves has a light, compact construction, and permits easy handling when compared with conventional spring-diaphragm actuators.

The GLS Series sets the standard for control valves in its category around the world today.

The GLS Series Control Valve