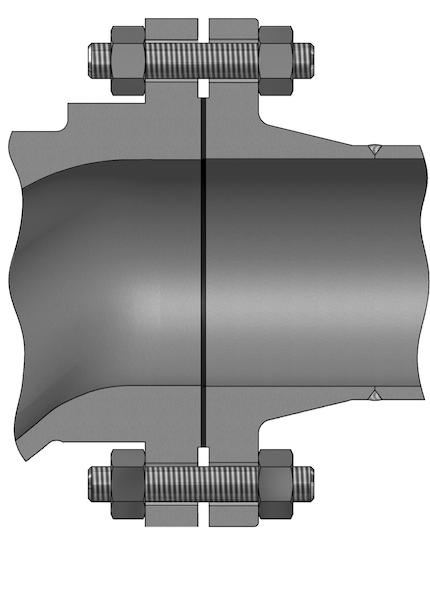

Integral Flanges

VBG Intech BG Series control valve bodies come standard with raised face surfaces in control valves equipped with integral flanges. For better sealing with adjacent piping flanges, the contact surfaces of control valve flanges are machined with spiral grooves. Other optional flange facing surfaces are available for the BG Series control valves upon request, such as: smooth finish, flat face, RTJ, large and small tongue, and large and small groove. In addition to the flanged versions, other types of end connections are available, such as: NPT Threaded connection, socket weld (SW), and buttweld (BW).

| Model | Valve Size | ANSI Class | Face-to-Face |

|---|---|---|---|

| BG-S | 0.5″ to 48″ | 150—600 | ISA 75.08.011 |

| BG-H | 1″ to 24″ | 900—2500 | ISA 75.08.011 |

1Valves larger than 16″ have face—to—face dimensions according to VBG Intech standards.

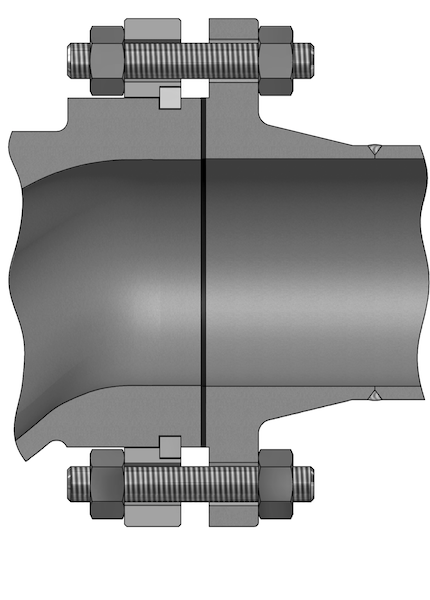

Separable Flanges

Process connections through separable flanges is optional for BG Series Control Valves up to 4 inches in ANSI Class 150, 300, and 600. Using separable flanges, an ANSI Class 600 body can easily be adapted to operate in ANSI Class 150, 300, or 600 services by means of a simple change of end flanges.

Separable flanges are generally supplied in carbon steel, as a cost effective solution, although flanges in stainless steel may also be specified to meet special requirements of operating temperatures and/or aggressive processes.

| Model | Valve Size | ANSI Class | Face-to-Face |

|---|---|---|---|

| BG-S | 0.5″ to 4″ | 150—600 | ISA 75.08.07 |

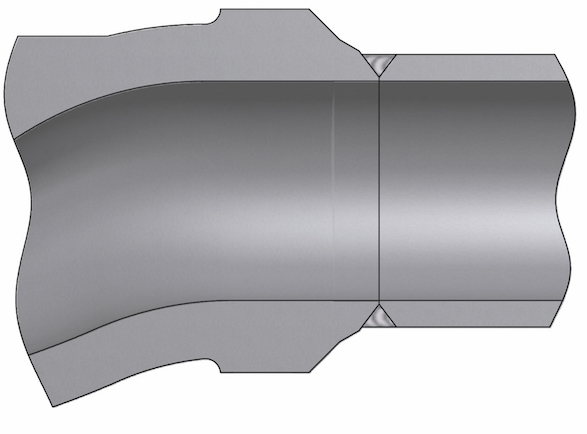

Other End Connections

In addition to the flanged end connections, other types are available for BG series control valves such as NPT threaded connection, socket weld (SW), and butt weld (BW).

| Model | End Connection | Valve Size | ANSI Class | Face-to-Face |

|---|---|---|---|---|

| BG-S | Buttweld | 0.5″ to 36″ | 150—600 | ISA 75.08.052, 3 |

| BG-H | Buttweld | 1″ to 24″ | 900—2500 | ISA 75.08.052. 3 |

| BG-S | Socketweld | 0.5″ to 4″ | 150—600 | ISA 75.08.032 |

| BG-H | Socketweld | 0.5″ to 4″ | 900—2500 | ISA 75.08.032 |

| BG-S | NPT Threaded | 0.5″ to 2″ | 150—600 | ISA 75.08.032 |

| BG-H | NPT Threaded | 1″ to 2″ | 900—2500 | ISA 75.08.032 |

| BG-H | Grayloc | 1″ to 24″ | 900—2500 | N/A |

2Long Pattern

3Valves larger than 18″ have face—to—face dimensions according to VBG Intech Standards

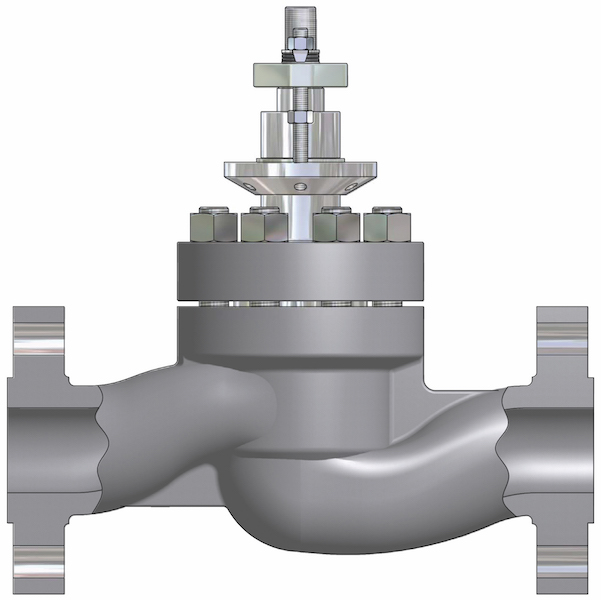

Bonnet Flange

The bonnet flange design of the BG Series control valves use a separable flange concept, not integral to the bonnet. As the bonnet flange does not come into contact with the operating fluid, it is normally manufactured in carbon steel; however, it may be manufactured in stainless steel or other materials to match the body if this is required due to the operating temperature or aggressive process.

Bonnet Flange Bolting

The VBG Intech BG Series Control Valves (with the exception of the BG-X) utlize a separable bonnet flange concept that is attached to the control valve body by means of studs and nuts. The standard material is ASTM A193 Gr. B7 for studs and ASTM A194 Gr. 2H for nuts, suitable for operating temperatures from –20º to 800ºF (–28º to 426°C).

Optionally, studs and nuts may be supplied in stainless steel, suitable for temperatures from –425º to 1500ºF (—253º to 815ºC). These temperature limits are valid for maximum operating pressures as stated in ANSI B16.34. Optional Xylene or Top Coat coated studs and nuts, as well as NACE compliant material can also be provided on request.